[FAQ-PACK-3]What is the safe way of lead bending Through Hole packages?

In some instances, the package leads must be bent in order to properly align their pitch with that of the drilled holes in the PCB. When lead bending is necessary, these general guidelines should be followed:

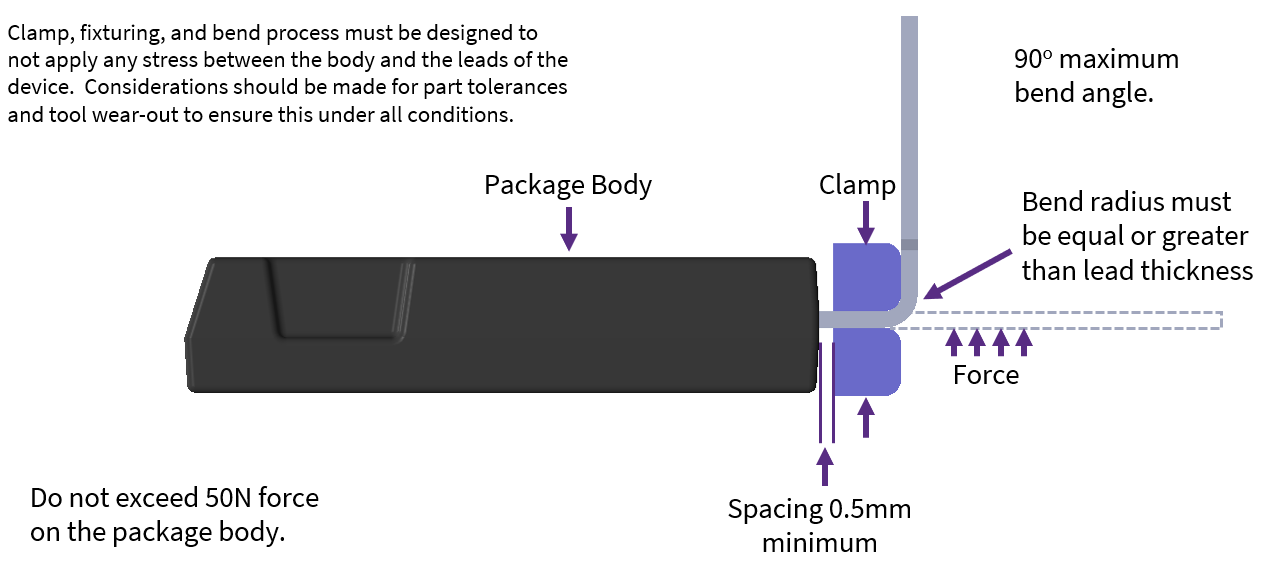

- A suitable clamp on the leads between the package body and the bend is required to eliminate any

mechanical stresses from being transferred to the package body

- Clamping force should be enough to ensure no movement of the clamp on the lead during the

bending process

- Clamping force should not be excessive which can cause lead deformation or weakening

- The clamp must not contact the body of the device under any circumstances during the bending

process. This can transfer stress into the mold compound and result in damage to the part.

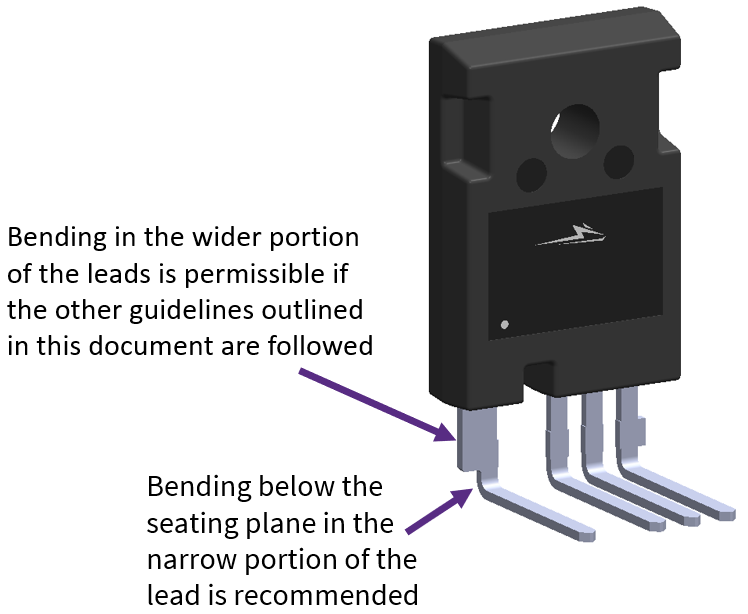

- Minimum recommended spacing between the body and the clamp is 0.5mm, however it is

recommended to perform the bend after the narrowing of the lead (seating plane).

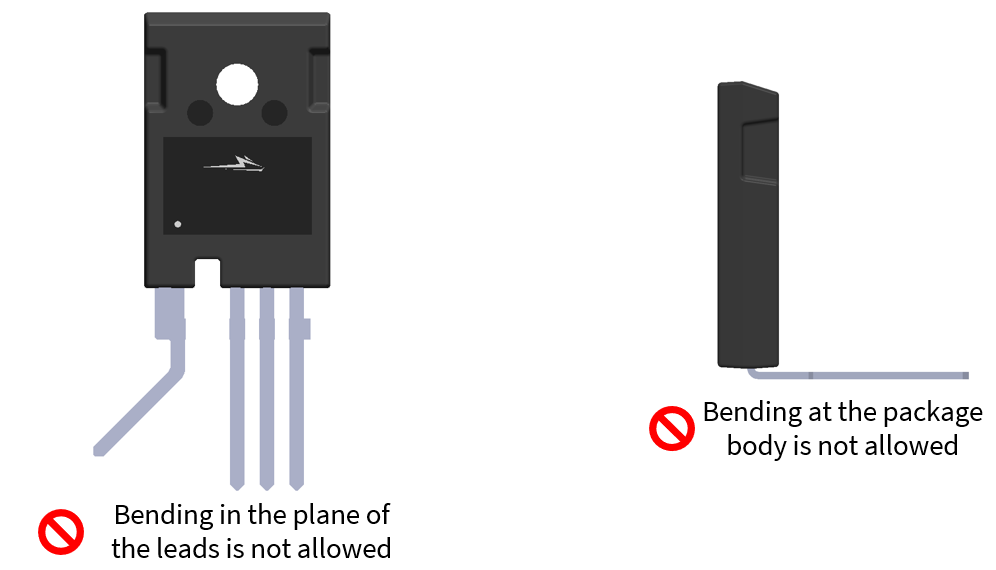

- Bending the leads at the package is not allowed. A clamp must always be used on the leads.

- Bending leads laterally (parallel to the body plane) is not allowed

- Leads may be bent a maximum of 90ᵒ up or down. Do not unbend or repetitively bend the same location