Determine Tj during a CIL measurement

I am using a CRD-CIL12N-XM3 evaluation PCB with a CAB450N12XM3 module and a CGD12HBXMP gate driver, with the module mounted on a hot plate to do thermal tests. I measure the temperature of the base plate and assume that Tj equals the hot plate temperature. I want to estimate the "true" Tj and read somewhere that I could use SpeedFit software to get a better estimate of Tj. How do I set up SpeedFit to do this? The configurations in SpeedFit do not match the CIL pulse test configuration of the module.

Comments

-

Hello petercs,

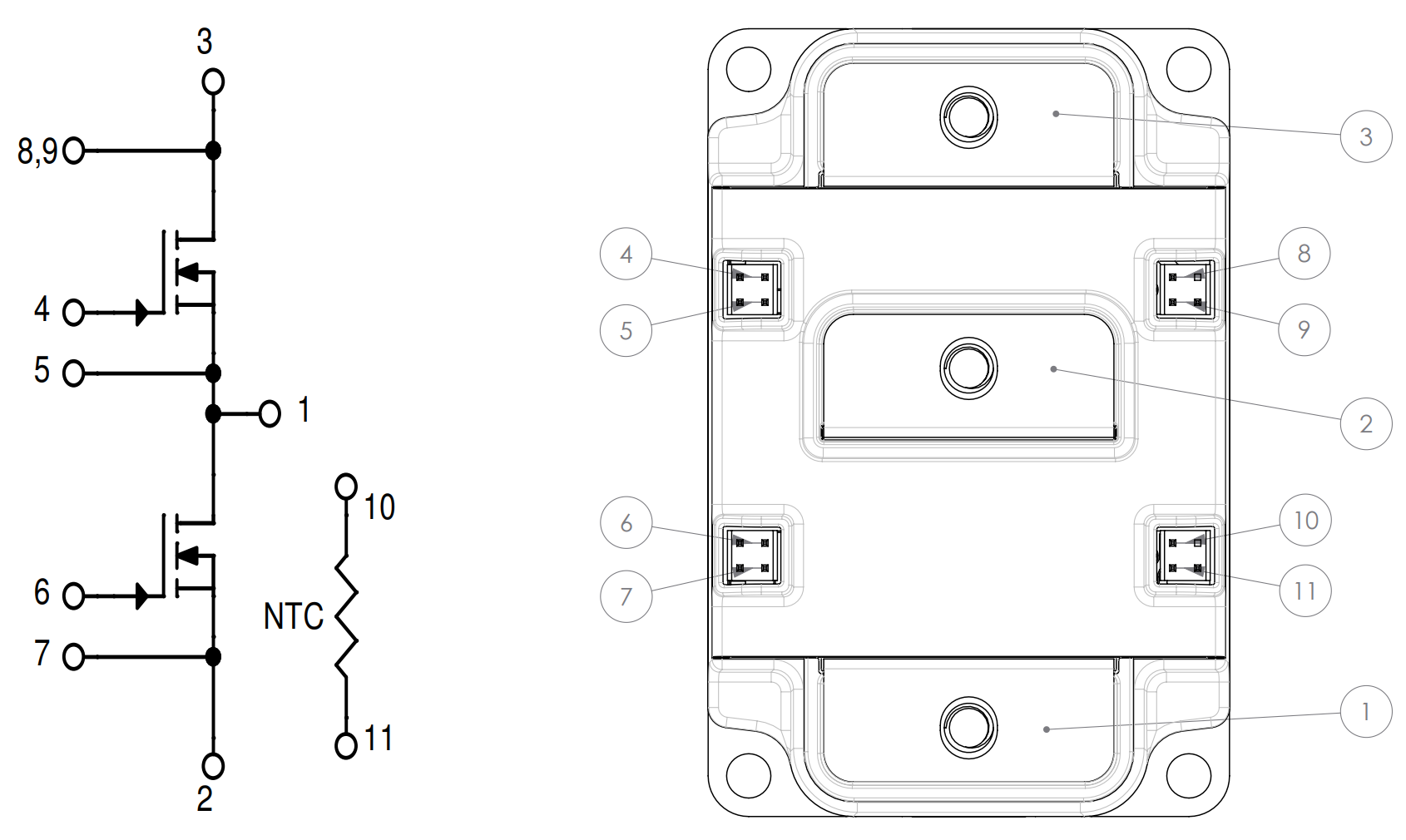

Thank you for your question. SpeedFit is a powerful simulation tool for predicting temperatures and circuit performance in converters. We recommend employing it when designing and developing new converters, and we hope you have found it useful for your other applications. However, the SpeedFit models are developed for evaluating performance of devices while they are operating in a converter, not evaluating a module with clamped inductive load or double-pulse testing. Therefore, we do not recommend using SpeedFit for this temperature estimation. To provide a better estimation of Tj for your application, we recommend that you monitor the temperature sensor (NTC) inside the power module. The NTC can be accessed through pins 10 and 11 of the XM3 power module.

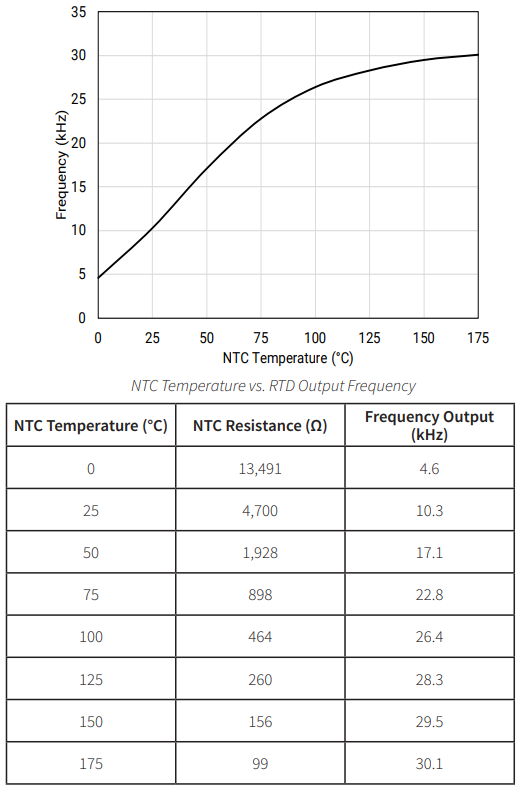

The recommended approach to monitor the NTC temperature is through the built-in NTC feedback signal of the CGD12HBXMP gate driver. This signal is in the form of a differential pair and can be monitored directly from the gate driver input connector. Referring to the CGD12HBXMP datasheet, these signals are "RTD-P" (Pin 9) and "RTD-N" (Pin 10). The measured NTC resistance is encoded by the gate driver into a frequency which can be decoded by a host controller. The characteristics of the frequency encoding is provided in the datasheet and also shown below.

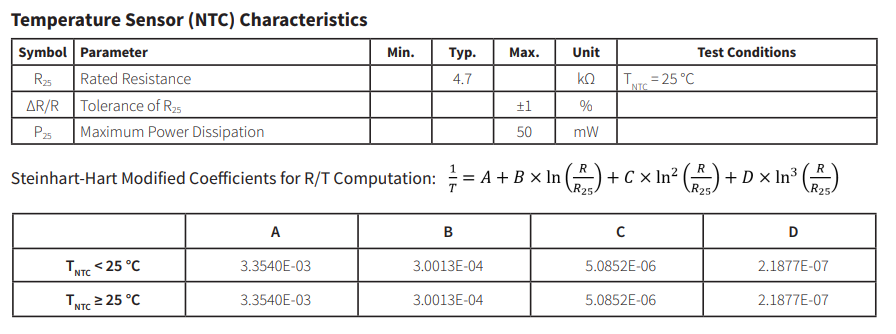

Alternatively, you can measure the NTC resistance directly using a multimeter or similar instrumentation. Please note that this measurement should be performed with isolated instrumentation (such as a battery operated multimeter) to avoid introducing parasitic ground connections into the circuit. The measured resistance can be converted to a temperature using the NTC characteristics provided in the CAB450M12XM3 datasheet and shown below.

Thanks,

Chris N.

0 -

Hi Chris, thanks for the prompt reply and useful information. I will monitor the NTC signal as a back up to the base plate temperature we are already monitoring. The CIL test we carry out looks at signals in the usec (and nsec) time scales. The idea behind using SpeedFit, which we can't use, was to look at Tj changes over a 50usec time frame during the test. Could we use a Spice model? The MOSFETs have a Tj pin, can we set up an equivalent circuit to the thermal environment? Do you have an app note? Best Regards, Peter. Peter Cox-Smith, Cox-Smith Consultants Ltd.

0 -

Hi petercs,

Thank you for the follow-up question. Typically, clamped inductive load (CIL) testing is used to determine the device switching dynamics at various temperatures. These experiments are generally performed by externally heating the device and observing the switching dynamics while at the target temperature. In these typical measurements, the NTC is a suitable method for measuring device temperature.

The Tj pin in the LTspice models is generally used as an input parameter. In these cases, the models are employed by manually setting the operating temperature of the device and observing the switching dynamics while the device operates at the target temperature. Monitoring the Tj pin in the model is not recommended as a "truth" parameter for CIL measurements because this parameter has not been validated in CIL experiments, due to the difficulty in performing that measurements experimentally as you mentioned.

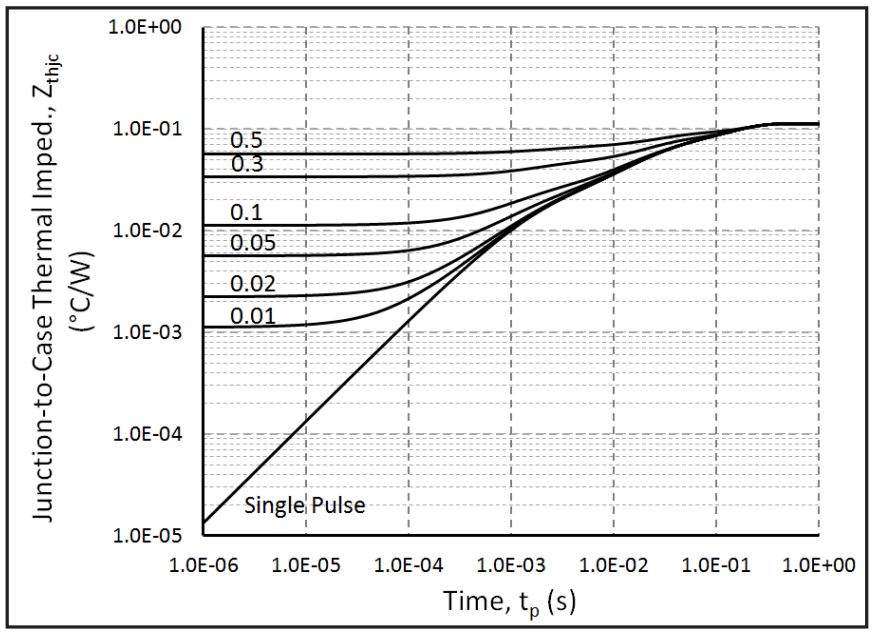

It is noted that during a short duration CIL experiment, the device self heating is minimal. Referring to the thermal impedance plot of the CAB450M12XM3 datasheet (and shown below), in short time durations, the junction-to-case thermal impedance is negligible. Thus, the junction temperature will be close to the measured baseplate temperature for the duration of CIL experiment.

Although these models are not developed for estimating temperature increase during CIL experiments, they are powerful tools for predicting system performance during converter operation. Wolfspeed offers SpeedFit, PLECS, and LTspice models online. The PLECS and SpeedFit models provide strong estimates of power losses and temperature increases when the device(s) is operating in a full-converter, and the LTspice models strongly predict dynamics such as overshoots and ringing frequency. These models are well-suited for predicting the performance of a full converter. More information on how to best utilize these models can be found here.

Thanks,

Chris N.

0 -

Hi Chris, thanks again for the comprehensive reply. I have used Tj as an input with the LTSpice model and with PSpice. And I'll use the base-plate temperature as Tj, which was the plan at the start of the tests. It was just a case of whether any further refinement was possible. Best Regards, Peter

0