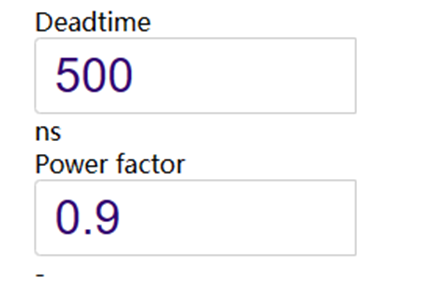

deadtime

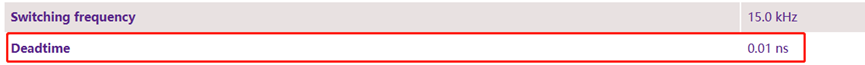

Regarding the dead time, taking CAB450M12XM3 as an example, when the dead time of the simulation condition is set to 500ns, the dead time in summary is displayed as 0.01ns. There are similar problems under other simulation conditions, namely: The dead time of the simulation condition is not consistent with the dead time shown in the results. In this case, what is the actual dead time in the simulation process? Is it 500 or 0.01? Namely: Is it a problem of simulation conditions or summary? If it is a problem of simulation conditions, can this problem be solved?

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0 -

Hi,

This is a problem associated with the data that is being tabulated in the summary pane. The mapping that happens from the input space to the simulation is not exactly the same sequence as the mapping to the summary page. I'll fix this as soon as possible, thanks for bringing it to my attention.

Thanks,

Zack

0 -

So I would like to ask, in this example, is the actual dead zone time in the simulation process 500ns?

0 -

In addition, I would also like to ask if you can provide some principles or references related to this thermal simulation model. Something like Application note. So that I can speculate on the cause of these problems with dead time based on this information.

0 -

Hi,

Currently, we do not have an application note with specific guidance on deadtime selection.

The minimum deadtime will be determined by gate resistance. We have validated that 400 ns is possible with aggressive gate resistance and excellent gate drive design, but 500 ns is a safer value and what we generally recommend for the CAB450M12XM3. If you are using a more conservative gate resistance, you may require higher deadtime. Using up to 1 µs is not uncommon, though of course diode losses during deadtime increase proportionally.

You could do some basic investigation with the SPICE model on our website (https://assets.wolfspeed.com/uploads/2020/12/all_sic_module_ltspice_models.zip), but the best solution is testing your design or using our evaluation kit (https://www.wolfspeed.com/products/power/evaluation-kits/kit-crd-cil12n-xm3/).

I hope that helps!

Blake W Nelson

0 -

Hi, I hope that this answered your question. I will close this discussion for now but if you have a follow up question, please "Start a New Discussion" and we would be glad to support you further.

0