Reflow capability of C3M0040120K Thermal Tab

Hi Wolfspeed Expert

To improve thermal hanlding capability, customer would like to use reflow process to solder thermal tab of TO-247 on DBC. would you kindly check if our C3M0040120K can support this reflow process

If it is supported, nice to have a recommend soldering profile from Wolfspeed, thanks.

Mason

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0 -

Hello,

The TO-247 package is not rated to handle the reflow temperatures of most solders if the part is being soldered directly to a heatsink (acting almost as an SMT part in this case). There is risk of delamination and reliability concerns if the part is used in this manner. With that being said there are some customers who use parts in this manner and have seen good results, but due to lack of testing internally and what we have currently experimented with, we can not recommend assembly in this fashion and will not accept returns if used in this manner.

Thanks

0 -

Thanks , it is clear.

0 -

Hi BGochis,

I have similar question, if our top side cooling package (U2) have the drain pad soldering capability. thanks

0 -

Hello,

Same answer as for the TO-247. It is not qualified but we have seen it done before without any issues

Thanks

0 -

Gochips,

Thanks for your kindly reply, can I ask what would be the cause of delamination if reflow solder the TO247 or TSC, EMC material,die attach or soldering temperature ?

0 -

If delamination were to occur in the package at these elevated conditions it would be at the EMC level. The die attach can easily withstand these temperatures but depending on how the package was handled prior to reflow (aka out of moisture safe bag, lab conditions etc..) some delamination could occur in the EMC which could lead to reduced reliability in the field. It's something that we would need to study further to specifically say it's "okay" to do this

Thanks

0 -

Hi BGchis,

Thanks a lot for your kindly explanation!

Is that means EMC cannot withstand the reflow temperature (is the EMC of TO247 different from TO263) or need the handled prior to reflow (remove moisture, lab conditions etc..),

or though TO263 can be reflow soldering but its EMC do not need withstand high temperature , right?

expect we can provide related application note for some customers who can accept the specifically handling cost to achieve better thermal performance (solder on heatsink or DBC)

0 -

Through hole packages are designed to only handle lower temperatures as the reflow process does not subject the whole package to the elevated temperatures. SMT packages are carefully designed and packaged for shipping in a manner that allows them to handle the SMT reflow profiles they see during assembly.

After some internal studying that needs to be done, we potentially may release collateral to discuss this mounting method but we are not at that point just yet

0 -

Hi BGochis,

thanks so much for explanation. there are some questions from a key account customer.

first, Supposing no moisture in device, what is suitable reflow temperature profile for TO247, which would not cause delamination and reliability issue. second, do we have some any moisture elimination method before reflow soldering. third, how to evaluate the reflow result for TO247, can we provide some support for customer, so that help us to do some pre-study?

below is reflow soldering profile , is it need some change for TO247 that would not cause reliability risk

0 -

Tangwei,

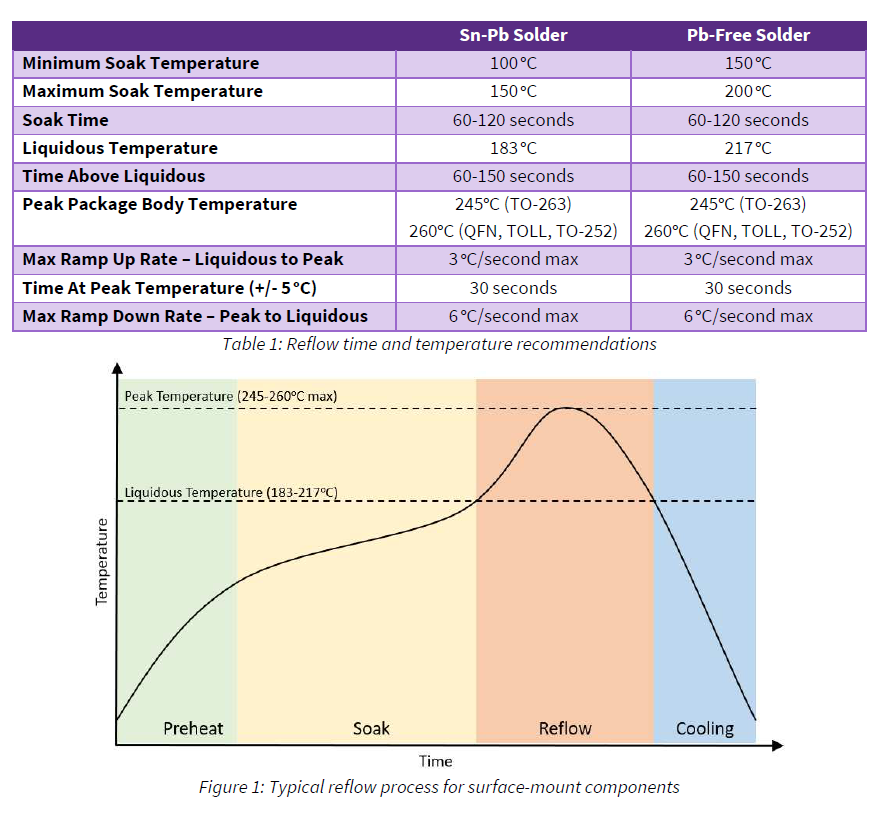

We have seen successful reflows using the two profiles below, one with a standard solder and one with a Pb free solder:

To eliminate/reduce moisture in the package prior to reflow, a standard pre-bake would be suggested to reduce the chances of any EMC issues.

To evaluate the result of the reflow, CSAM imaging provides a very good analysis of the results. It is suggested to image at solder interface, and die top level, to check for any voiding in the solder and also to look for any delamination in the EMC and to see if there are any wirebond issues

Thanks

0 -

Hi Hi BGochis,

Thanks a lot for your professional advice!

can we suggest the pre-bake temperature and time. in addition to these advice, do you have other suggestion to evaluation the process of reflow for TO247 package, thanks.

0 -

If this is used for an Industrial application, following JEDEC standard pre-bake conditions is recommended. This would be between 125C-150C bake and the time range can vary from a couple hours to 24 hours

0 -

Thanks a lot!

0 -

hello BGochis,

How are you doing well.

as you mentioned , we will have internal evaluation for the reflow process for TO247 package, can you share the some result if it is available.

we get info from evtol application, some customer consider using reflow process with DBC in propulsion inverter ,

they choose Automotive device , if it will be better than Industrial device?

looking forward your feedback , thanks

0 -

Hey Tangwei,

We don't have any results yet but this project has gained a lot more interest and I hope to have some results soon as it has been moved up the priority list. In terms of Auto vs Industrial, I don't believe there would be much of a difference in reflow performance of a THD because even for the Auto parts, they are not subjected to pre-bakes or MSL rated

Thanks

1

1 -

Hi BGochis,

thanks for your timely reply, looking forward the result and release related application note

0