Thermal Impedance - how to use this parameter

Please could you help clarify how the Thermal Impedance parameter (Zthjhs) is applied to thermal calculations (to SIC Modules with high and low side MOSFETs).

Referring to the CAB011M12FM3 data sheet Thermal Impedance graph (Fig 17), I understand that the x-axis 'Time, tp(s)' refers to the pulse duration (in seconds).

Q1) with a 0.5 duty, does the 'pulse duration' apply to the 'on time', or the 'cycle time' (on + off duration of each cycle)?

In our inverter application, the SpeedFit simulator predicts a 32C Junction to Case temperature rise for a CAB011M12FM3, which I believe is accurate. However, using hand calculations (based on data sheet Zthjhs), I calculate a significantly higher temperature rise (52C).

SpeedFit calculates total inverter loss to be 532W (three MOSFET modules, one per phase).

There are two devices per package, high-side and low-side. I note the each device comprises two separate junctions (areas on silicon), so four junctions in each module.

Q2) does the 'Zthjhs' parameter refer to each MOSFET device in the package (i.e. two devices, high and low), or to each junction (i.e. 4 junctions, two on low side MOSFET, two on high side MOSFET )?

Q3) what power dissipation should be applied to the Zthjhs parameter? I suspect that it should be the total loss per module (rather than per MOSFET device) i.e. total inverter loss divided by the three MOSFET modules 523W / 3 = 174W per module

Zthjhs (from Fig 17) 0.5 duty, 283Hz (3.53ms cycle time) = 0.3C/W (approx)

Junction to Case temperature rise = 0.3 x 174W = 52C, quite a lot higher than 32C.

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0 -

Hey Matt,

Q1) In the case of the Zth plots, Tp refers to the duration of the pulse, which should be interpreted as 'on time'

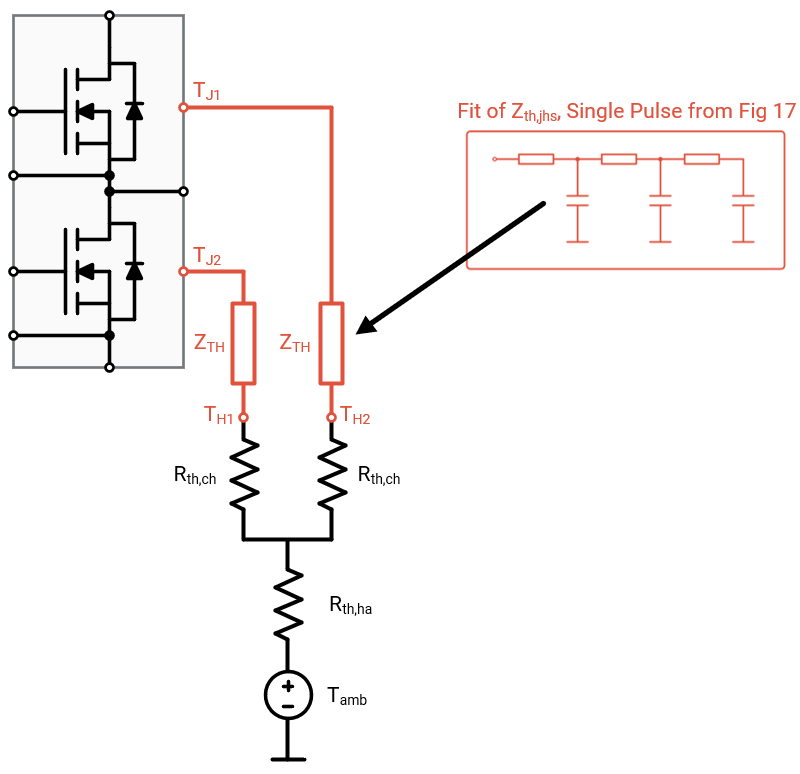

Q2) For the Wolfpack modules Zth,jhs refers to the thermal impedance between each switch position's junction and the heatsink (so this includes the package and TIM, but not heatsink to ambient impedance). For the CAB011M12FM3, there should be two impedances, one for the high side MOSFETs and one for the low side MOSFETs. Here is a figure showing how this works in SpeedFit:

The impedance "Rth,ch" is normally used to represent the TIM performance value, but since the Wolfpack models use Zth,jhs (instead of Zth,jc like other modules), you should set this value to zero. Rth,ha however, should still be above zero. It reflects the performance / quality of your thermal management system.

Q3) Following the conclusion from Q2, you should divide out the power among all 6 switch positions (2 per phase, 3 phases), so 523W/6 = 87.2W per switch position.

If you plug this into your prior equation, 0.3 x 87.2W = 26.2C does not match SpeedFit. My assumption is that your SpeedFit results also include a value for heatsink to ambient that would also need to be included in this calculation. Its also worth noting that the thermal model used by SpeedFit is based on a Cauer model fit of the 'single pulse' data, rather than using the duty cycle dependent results.

Hopefully this address your question, but let me know if you would like to discuss anything further.

Thanks,

Blake

0 -

Hi Blake,

Thanks for clarifying the subtleties of these definitions, that's made things a lot clearer.

I've now got the speedfit and hand calculation peak junction temperatures in reasonable agreement, so I'm confident in the design and device selection.

Best regards

Matt

0