Cold Plate doubts

Hi there,

I've several doubts regarding the performance of the cold plate installed at CRD300DA12E-XM3 Three Phase Inverter (CP 3012 from Wieland).

· Which is the maximum admissible flow rate? In the datasheet it seems to be 25 l/min. Is that right?

· Which is the maximum coolant pressure?

· Which is the power to be dissipated by the coolant when the inverter is working at maximum power (300kW) at a switching frequency of, for instance, 20 or 24 kHz?

· In section 2.6 of the product datasheet it is said that "Maximum output power is de-rated when operating with coolant temperatures above 25ºC". Where can I find the definition of this re-rate?

· Does the inverter by itself limit the performance for assuring that the mosfet respects the SOA (safe operating area) depending on the DC voltage and/or the switching frequency? Does the de-rate commented above related to this?

· It is also mentioned that 50/50 mixture of water/ethylene glycol is suggested. But, in our case, we're no foreseeing to use the inverter in an ambient less than 0ºC. Is there any information about the performance when operating without glycol, 100% water or 100% deionized water?

Another question I have is: which is the low voltage power consumption?

Best regards,

Borja

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0 -

Thanks!

0 -

Hi Borja,

25 L/min is not a limit, but you start to get diminishing returns with significant pressure drop above this flow rate. The cold plate has been leak tested to 50 PSI as well.

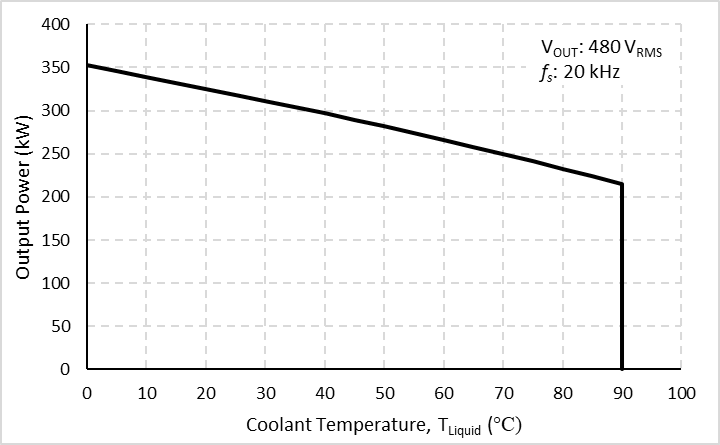

The maximum power dissipation at 300 kW, 25 C coolant, and 20 kHz would be roughly 4500 W. The power derating curve for 20 kHz is provided below as well.

The inverter does not self limit in any way. The derating mentioned is a thermal/power dissipation limitation to keep the junction temperature of the devices below the maximum rated value of 175 C.

Since this cold plate is aluminum, 100% water or deionized water is generally not recommended as it will be corrosive.

A 12V/5A supply is suggested to account for higher switching frequencies.

Thanks,

Jonathan

0 -

Hi Jonathan,

Many thanks for your reply. I just have a couple of questions pending.

- Where can I find the curve Output Power vs Coolant Temp you posted? I've not found it in the converter's user guide.

- Regarding the inverter limit by itself, is then a limitation of the Output Power vs Switching Frequency? If so, could you provide that curve?

Best regards,

Borja

0 -

Hi Borja,

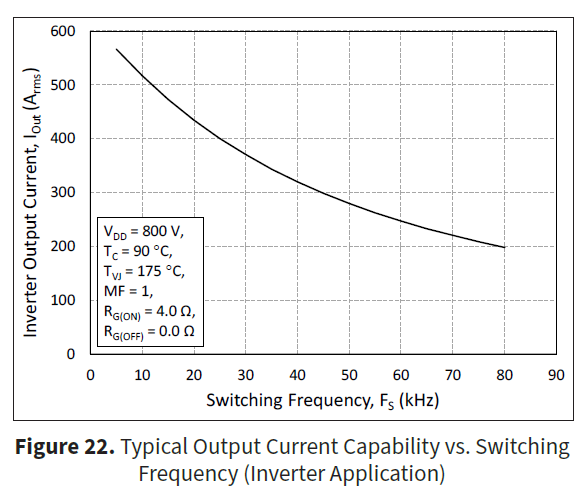

The curve I posted is a derivation of the CAB450M12XM3 ampacity plot shown below that can be found in the module datasheet, but with an conservative Rth,junction-to-liquid value for the entire stack-up of the inverter kit.

This data is not published, but if you can work with your local or regional Wolfspeed sales team, we can provide this data so you can manipulate the curve based on the operating points of interest.

Thanks,

Jonathan

0 -

Hi Jonathan,

Thanks for clarifying this. Really appreciated.

Borja

0 -

Hi, I hope that this answered your question. I will close this discussion for now but if you have a follow up question, please "Start a New Discussion" and we would be glad to support you further.

0