CRD25DA12N-FMC PCB Design Related

We have couple clarifications related to the PCB design for the 25kW CRD25DA12N-FMC V1.1

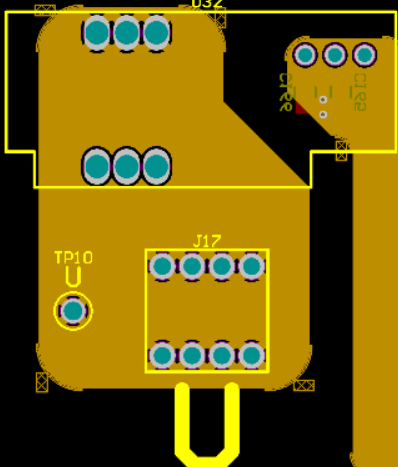

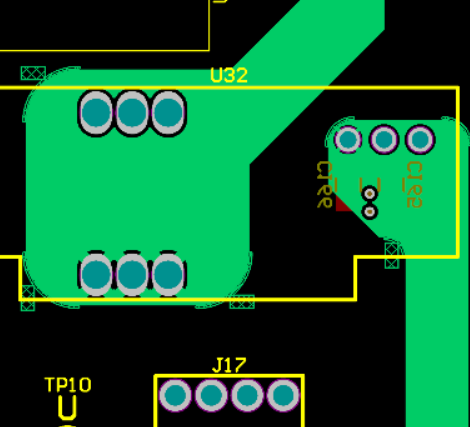

- The hall sensor is oriented in such a way the input and output traces of the phase leg current paths are in zig zag as below . if the component was 180 shifted it would have been phase leg out to hall in , hall in to terminal and no need for criss crossing the power traces, any reason this approach was chosen

Hall sensor output to J17

Phase leg output to hall sensor

Making this 180 degree shift (U32) makes a clean connection path easier . curios any constraint prevented this hall sensor position ?

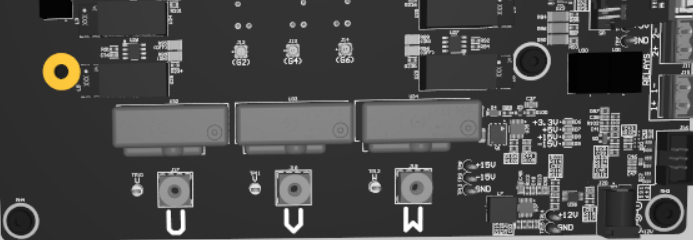

2. Why are all the 4 mounting holes for SiC Module Heatsink (and the 4 pcb mounting as well) done as gold plated through hole instead of regualr mouting hole only, they are very close to the vicinity of parts and can become a stub through the heatsink

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0 -

Hello mavern1,

Thank you for your interest in this design. I answered your two questions individually below.

- The pattern of the input and output orientations of the hall effect sensor follows the guidance of the sensor manufacturer for high-speed PCB design. Page 7 of this document from LEM provides more information about this design choice.

- We prefer to use metal hardware for mounting the heat sink to the PCB to provide a strong mechanical connection and to electrically link the heat sink potential to the GND potential on the board. When using metal hardware, the mounting hardware itself can create a short circuit to electrical traces/pours on the board without a proper design rule in place. By making the mounting holes conductive with an annular ring diameter slightly larger than the mounting hardware, it is easy to configure a design rule to prevent unexpected short circuits through the hardware.

Thanks,

Chris N.

0 -

Hi, I hope that this answered your question. I will close this discussion for now but if you have a follow up question, please "Start a New Discussion" and we would be glad to support you further.

0