Thermal Design guidance for 60 kW Dual Active Bridge Isolated DC/DC Converter

Hello Team,

I am designing 800 V, 100 KHz, 20 kW Dual Active Bridge DC-DC converter for solid state transformer using power modules CBB011M12GM4.

Here I am requesting for Thermal design guidance for 20 kW power level, Heatsink cooling selection, Junction-case and case-ambient thermal calculations, power loss density and safe operating temperature limits and recommended part numbers.

Any reference thermal design and application notes would be helpful.

Thank you.

Comments

-

Thank you for your post, it has been approved and we will respond as soon as possible.

0

0 -

Thank you and we will be waiting for your response.

0 -

Hello danusha,

A lot of the thermal design is going to be based on the power loss budget in order to identify how much heat needs to be extracted from the system. I recommend using the Wolfspeed SpeedFit platform as a starting point for estimating losses at your target operating conditions. Wolfspeed also provides PLECS and LTspice models of all our power modules here which can be used for more advanced simulations.

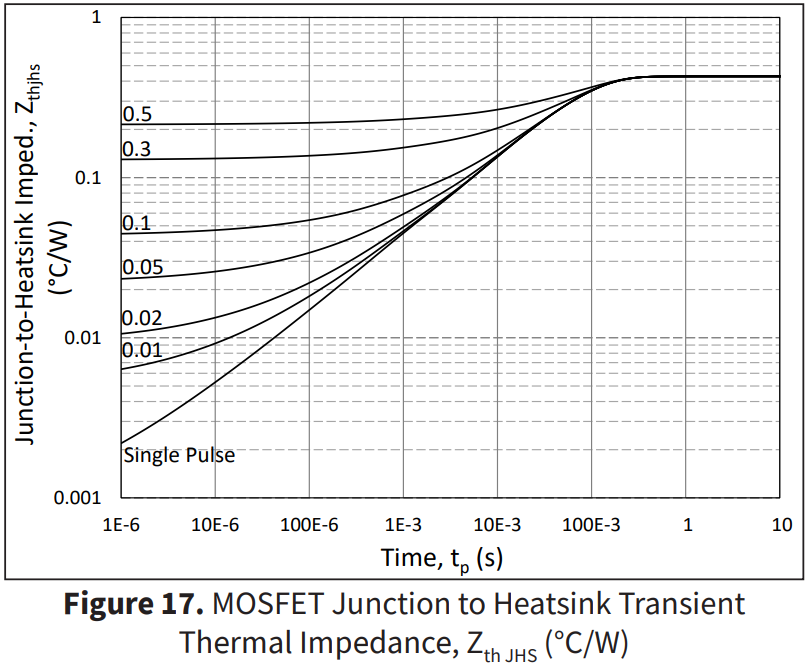

The application note "Thermal Characterization Methods and Applications" (PRD-08376) provides a lot of useful information for your design efforts. I recommend reviewing that application note for more details. Additionally, the datasheet for the CBB011M12GM4 includes a junction-to-heatsink thermal resistance value and thermal impedance plot (shown below). These can be used for estimating thermal performance and are already included in the PLECS and LTspice simulation files. The measured thermal resistance/impedance includes the influence of Wolfspeed pre-applied thermal interface material (TIM) which comes on the CBB011M12GM4T variant by default.

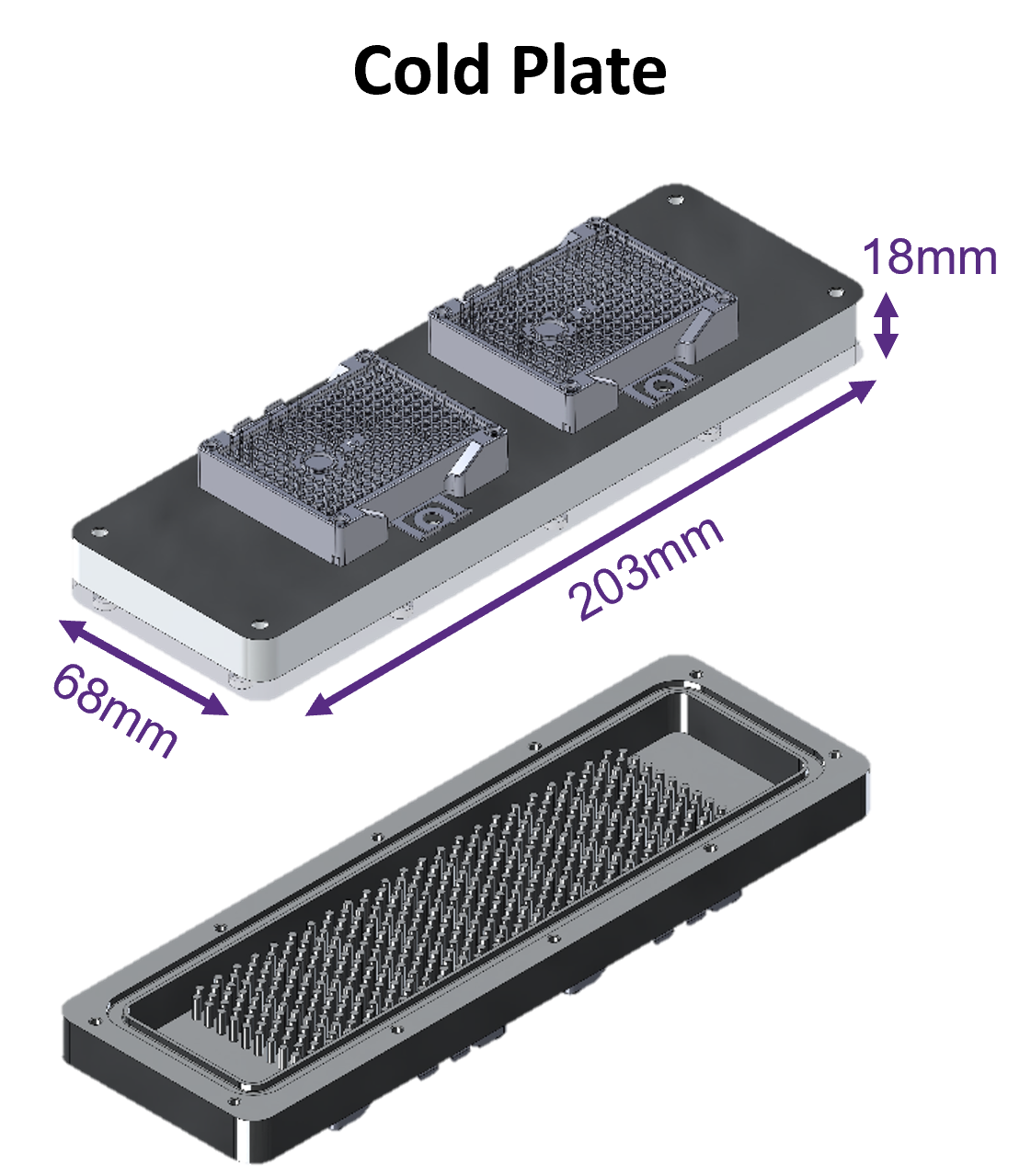

The CRD60DD12N-GMB uses a custom cold plate solution with integrated fins for improved thermal performance. It has a measured heatsink-to-fluid thermal resistance of 0.045 °C/W. I attached the STEP files for the cold plate design and a picture of the fins below for reference. This cold plate can be used as a starting point for your design, though it can likely be simplified due to your lower power requirement (20 kW instead of 60 kW).

Thanks,

Chris N.

0 -

Thanks.

0